LCM, namely LCD display module and LCD module, refers to the assembly of LCD devices, connectors, peripheral circuits such as control and drive, PCB circuit board, backlight, structural parts, etc. In the home theater, LCD has become the mainstream, bringing joy to more families. LCM module is widely used in electronic equipment. Calculators, mobile phones, notebooks, learning machines, electronic dictionaries, tablet computers, desktop LCD screens, LCD TVs, on-board display instruments, GPS navigators, industrial control operation and display interfaces, medical instrument displays, etc. Next, the manufacturer of Sinocrystal LCD module will introduce what LCM module is:

According to the module structure, it can be divided into:

1. the chip is bonded on the glass;

2. the chip is bonded on the PCB;

3. anisotropic conductive adhesive connection mode: fix the IC with TCP (tape carrier package) on LCD and PCB with anisotropic conductive adhesive;

4. the wafer is directly mounted on the flexible film (peripheral components can be mounted on the flexible film together with IC);

5. other categories: for example, there are digital display module, dot matrix character module and dot matrix graphics module according to the display content, and there are normal temperature and wide temperature types according to the temperature.

According to the display mode, it can be divided into:

1. positive image display (+v)

2. negative image display (-v)

3. transparent display

4. reflective display

5. semi transparent display

According to the display mode, it can be divided into:

TN type: 90 ° twist, low working voltage, small viewing angle, and driving duty cycle of 1/4 ~ 1/8. The display is black / white. Low cost and selling price;

HTN type: 110 ° twist;

STN type: 180 ° ~ 250 ° twist, slightly higher working voltage, significantly larger viewing angle than TN type, and the driving duty cycle is more than 1/4 ~ 1/8. The display is yellow / blue or black / white. The cost and selling price are higher than TN type;

FSTN type: stn+ single layer compensation film;

FFSTN type: stn+ double-layer compensation film;

DSTN type: double layer STN box.

IV Connection mode

FPC connection: a flexible printed circuit is used. One side is connected with the electrode of the LCD screen through ACF, and the other side is connected with the control board of the driving circuit. Due to the good reliability, high integration and small size of this module. Commonly used in mobile phones, MP3, electronic dictionaries, etc.

Metal pin pin connection: crimp a metal pin to each electrode of the LCD screen, and then directly insert the metal pin into the set connection motherboard when necessary. The connection is convenient and stable, and is widely used. However, the display content is limited by the number of pins (pitch 1.27min).

Zebra strip connection: a conductive adhesive strip is used. One side of the adhesive strip is connected with the electrode edge of the LCD display, and the other side is connected with the main board of the driving circuit. This kind of module is often used in instruments and meters. It has many display contents, but its volume is large.

Hot pressed zebra paper connection: use a piece of conductive paper with the same width and number of electrodes as the LCD to crimp one side of the zebra paper to the electrode edge of the LCD and the other side to the driving motherboard through hot pressing (Zebra paper minimum pitch 0.18) Because zebra paper is soft, it can adapt to different structural parts and assembly requirements in use, and can realize thin installation.

ACF (anisotropic conductive adhesive) connection:

a) COG (chip on glass) presses the chip on the LCD Display. Therefore, the volume of the whole module is relatively small. Cog can achieve higher bonding accuracy (our company's bonding pitch 35um min). This method is most suitable for liquid crystal displays which are becoming smaller and display more and more information Therefore, it has broad prospects and practical value.

b) Tab & COF means that the chip is bonded on the flexible circuit board, and then the flexible circuit board is hot pressed and connected to the LCD. It can achieve the connection density of more than 14 lines /cm (our company states pitch0.11mm min) It is indispensable for high-precision, large capacity, ultra-small and ultra-thin products such as liquid crystal display.

LCM main materials:

LCD :TN, HTN, STN, FSTN, etc。

Backlight: a) LED backlight: bottom backlight, side backlight, color screen backlight; b) El backlight; c) CCFL backlight.

IC: cog type, cob type, tab type and COF type according to the packaging form.

PCB: printed circuit board, mostly double-sided boards in LCM.

Fpc: flexible printed circuits flexible printed circuit connector, including single panel, double-sided board, hollow board, multilayer board and layered board.

FFC: flat flexible cable.

Hsc:heat seal connector zebra paper.

Zbc:zebra connector zebra conductive adhesive connector.

BZF & plf:bezel iron frame, plastic frame.

Touch panel: touch screen.

Connector: connector.

ACF: anisotropic conductive adhesive.

Res/cap resistance capacitance and other electronic components, double-sided tape, black / White Silicone Tape and other materials.

Introduction to common terms in LCM LCD module manufacturing process:

Tft----- thin film transistor

Cf--------color filter: color filter

Lcd----- liquid crystal display

Tab----- tape automatic bonding: on load packaging IC

PCB printed circuit board

Acf----- anisotropic conductivefilm: anisotropic conductive film

B/l-------back light: backlight module

Assy--- assembly: assembly

B/z-------bazel: iron frame

Bonding: pressing

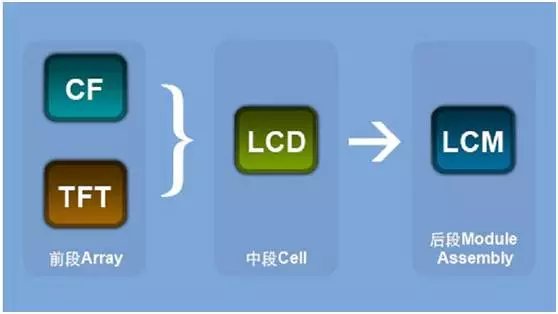

"Front, middle and rear" sections of TFT-LCD manufacturing

What is LCM liquid crystal module and its structure

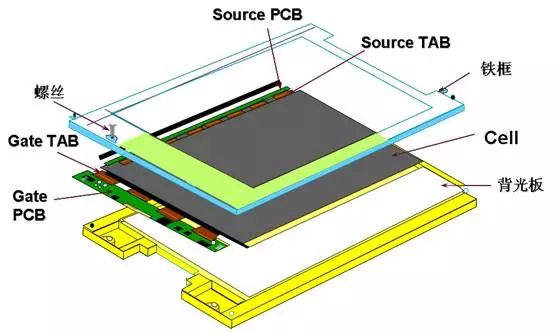

As shown in the figure above, the latter module process is mainly the integration of the driving IC of the liquid crystal substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the driving IC to drive the liquid crystal molecules to rotate and display images. In addition, the backlight part will be integrated with the LCD substrate in this link, and the complete LCD panel will be completed.

Front array:

Film

Yellow light

Etching

Film stripping

Middle section cell

Alignment film printing

Sealant coating

Spraying spacer

Injecting liquid crystal

Sealing combination

Polarizer attachment

Rear module assembly:

11. Cog process

12.Soft circuit board pressing

13. Printed circuit board pressing

14. Backlight module assembly

15. Aging test

Main structure diagram of LCM liquid crystal module

The 8 inch displays might be affected and delay for an accident.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

This is the project management of how sinocrystal handle your customized project relate to displays.

Sinocrystal provides a secure and reliable packaging system for LCD displays, ensuring maximum protection against shock, moisture, and static electricity during global transportation.

Discover how LCD displays are evolving in industrial automation — from high-brightness and rugged designs to smart connectivity and energy efficiency. Explore what’s next for industrial-grade visual interfaces.

Discover the key factors to consider when choosing an LCD display for your project, including size, resolution, interface, brightness, and customization options from a factory-direct manufacturer.

Discover the latest innovations in rugged LCD displays for harsh environments — from extreme temperature resistance to sunlight readability and waterproof designs. Factory-direct manufacturing with full customization.