About LCD structure

LCD comes from the first letter of liquid crystal display. It’s a passive display component, that means they do not emit light, just use the ambient light in the environment. By manipulating this light, only little power just be used. This has made LCDs the preferred technology for low power consumption.

All of us known about LCD using fields, But how it works and what’s the inner structure?

A display module consists of display panel and driving part.

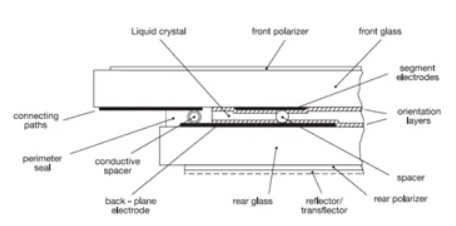

Here is the monochrome display panel’s basic structure.

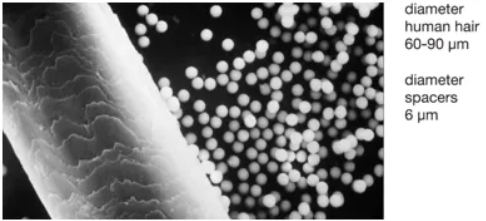

A liquid crystal cell consists of a thin layer (about 3~7 um) of a liquid crystal sandwiched between two glass substrates with transparent electrodes deposited on their inside faces. Because the liquid crystal layer just liquid so it can’t sustain the pressure, so here are some spacers between two glass substrates.

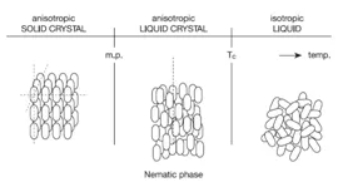

Liquid crystal is a key material for a LCD.

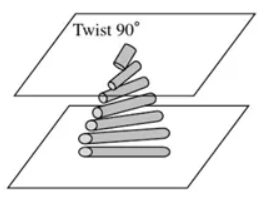

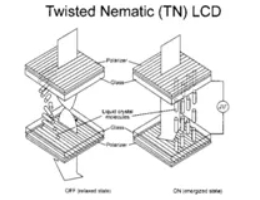

For Twisted Nematic LCD, the two surfaces PI are rubbinged orthogonal to one another, forming a 90 degree twist from one surface to the other,

This helical structure has the ability to control light. A polarizer is applied to the front and an analyzer/reflector is applied to the rear of the cell. When randomly polarized light passes through the front polarizer it becomes linearly polarized. It then passes through the front glass and is rotated by the liquid crystal molecules and passes through the rear glass. If the analyzer is rotated 90 degrees to the polarizer, the light will pass through the analyzer and be reflected back through the cell. The observer will see the background of the display, which in this case is the silver gray of the reflector.

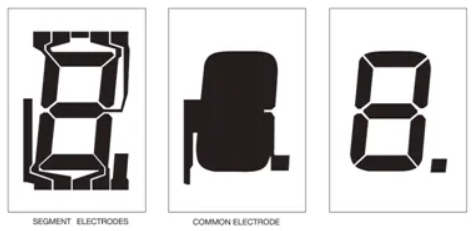

The LCD glass has transparent electrical conductors layer plated onto each side of the glass substrate in contact with the liquid crystal fluid and they are used as electrodes. These electrodes are made of Indium-Tin Oxide (ITO).

Below is a typical “8” electrode pattern.

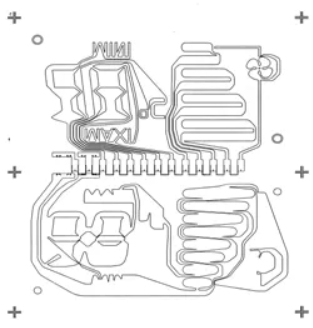

More complex pattern’s principle is the same.

The 8 inch displays might be affected and delay for an accident.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

This is the project management of how sinocrystal handle your customized project relate to displays.

Sinocrystal provides a secure and reliable packaging system for LCD displays, ensuring maximum protection against shock, moisture, and static electricity during global transportation.

Discover how LCD displays are evolving in industrial automation — from high-brightness and rugged designs to smart connectivity and energy efficiency. Explore what’s next for industrial-grade visual interfaces.

Discover the key factors to consider when choosing an LCD display for your project, including size, resolution, interface, brightness, and customization options from a factory-direct manufacturer.

Discover the latest innovations in rugged LCD displays for harsh environments — from extreme temperature resistance to sunlight readability and waterproof designs. Factory-direct manufacturing with full customization.