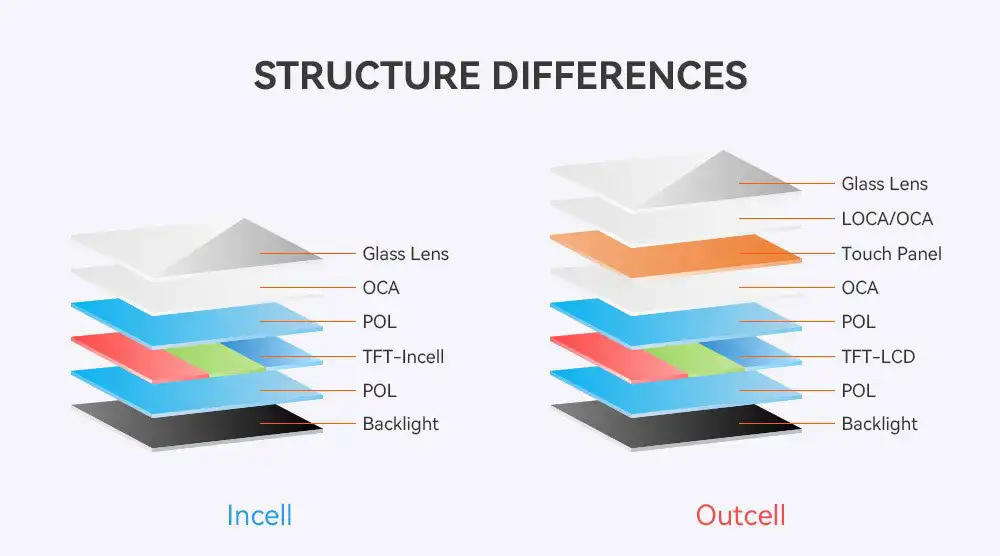

As touch lcd display technology evolves, designers and engineers are rethinking how touch is integrated into devices. Two major structures — Out-cell and In-cell — dominate the market, each with its own technical and cost advantages. This article breaks down their differences in performance, structure, and total cost, to help you select the best option for your product.

Out-cell is a traditional structure where the touch sensor is a separate component laminated on top of the LCD or display panel. It usually involves a custom-made capacitive touch panel (CTP), bonded to the display using air or optical bonding.

Flexible customization (touch structure, thickness, cover lens)

Easy to repair or replace

Mature, well-understood process

Thicker module

Higher cost due to custom CTP design

Higher tooling charge (CTP tooling + cover lens tooling)

Lower optical performance due to bonding layers

In-cell technology integrates the touch function directly into the display panel, typically inside the TFT structure. This means the touch sensor is already part of the display — no need for a separate CTP.

✅ Significantly lower cost — since there's no need to customize a CTP, you only need to design a cover lens. This reduces both the unit price and the tooling charge.

Thinner, lighter structure

Excellent optical clarity and transmittance

Fast, responsive touch experience

Easier assembly process

Slightly lower customization flexibility

Not ideal for very rugged or outdoor applications

Feature |

Out-cell Touch |

In-cell Touch |

Structure |

Touch sensor on top |

Touch embedded in display |

Thickness |

Thicker |

Ultra-thin |

Customization |

Full CTP and cover lens needed |

Only cover lens needed |

Unit Cost |

Higher |

Lower |

Tooling Charge |

High (CTP + cover lens) |

Lower (cover lens only) |

Optical Clarity |

Medium (extra bonding layer) |

Excellent |

Application Flexibility |

High |

Medium |

Repairability |

Easy |

More difficult |

Applications |

Industrial, kiosk, outdoor |

Consumer, smart devices, light-duty industrial |

✅ Out-cell CTP: Suitable for industrial lcd displays, rugged terminals, and custom-size lcd module devices where design flexibility and durability are priorities.

✅ In-cell CTP: Ideal for cost-sensitive, thin, and mass-produced products — including consumer electronics, smart home devices, and portable equipment.

While Out-cell offers more customization, In-cell is now becoming the smarter, cost-effective choice for many applications. With lower unit price, simplified assembly, and reduced tooling cost, In-cell displays help accelerate your time to market.

At Sinocrystal, we offer both In-cell and Out-cell CTP solutions tailored to your needs.

📩 Contact us today to explore the best-fit display technology for your product!

The 8 inch displays might be affected and delay for an accident.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

This is the project management of how sinocrystal handle your customized project relate to displays.

Sinocrystal provides a secure and reliable packaging system for LCD displays, ensuring maximum protection against shock, moisture, and static electricity during global transportation.

Discover how LCD displays are evolving in industrial automation — from high-brightness and rugged designs to smart connectivity and energy efficiency. Explore what’s next for industrial-grade visual interfaces.

Discover the key factors to consider when choosing an LCD display for your project, including size, resolution, interface, brightness, and customization options from a factory-direct manufacturer.

Discover the latest innovations in rugged LCD displays for harsh environments — from extreme temperature resistance to sunlight readability and waterproof designs. Factory-direct manufacturing with full customization.